HWH Leveling Valve

We have had leveling problems over the last year which were finally solved by replacing the raise valves on the front HWH “six pack”. We had been to a couple of service places that improved the situation but never really solved the issue.

I finally got around to disassembling the old valves to see if I could find out why they were misbehaving and here is what I found.

The valve is a simple electromagnetic NC (normally closed) valve. When power is supplied the valve is opened and when 12DC is removed the valve seals with its internal spring.

The valves contain a cone shaped seat, a plunger with a compliant insert that rests on the seat, and a spring to keep it closed when the solenoid coil is not energized.

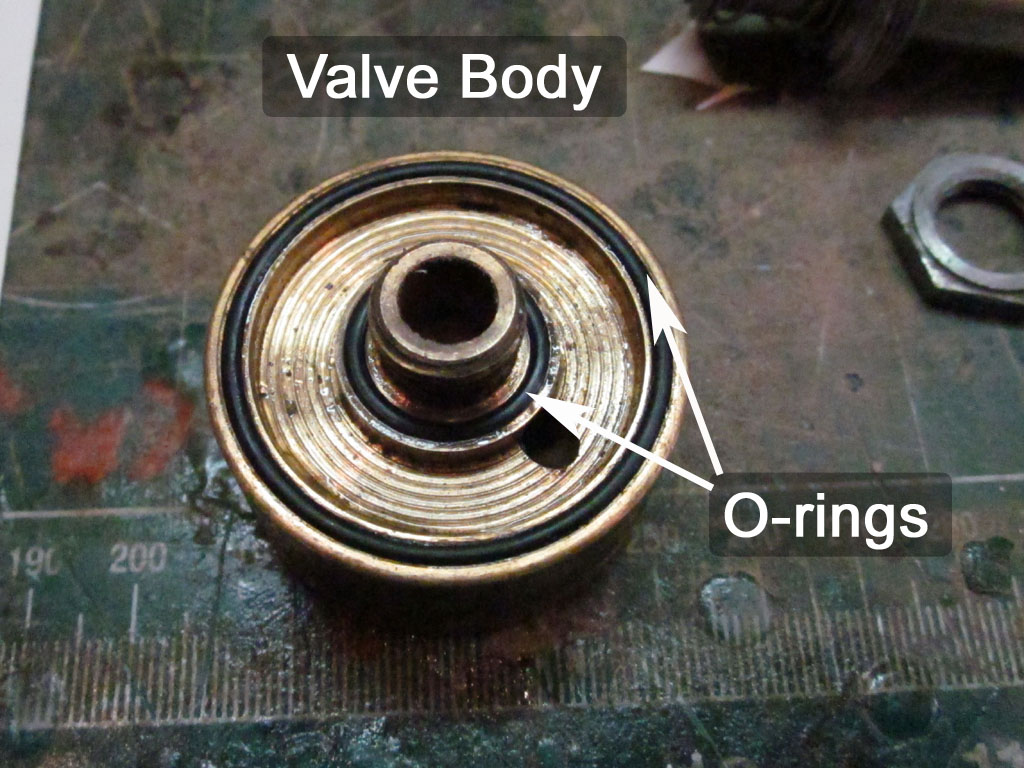

The valve stem is screwed on to the brass body, it seats on an internal O-ring to seal the stem and body interface. Inside the stem is a simple spring loaded piston with a compliant seal on one end. The spring presses the compliant seal, on the end of the piston, onto the cone shaped seat in the brass body to close the valve. Power to the electromagnet pulls the piston off the seat and allows air to flow.

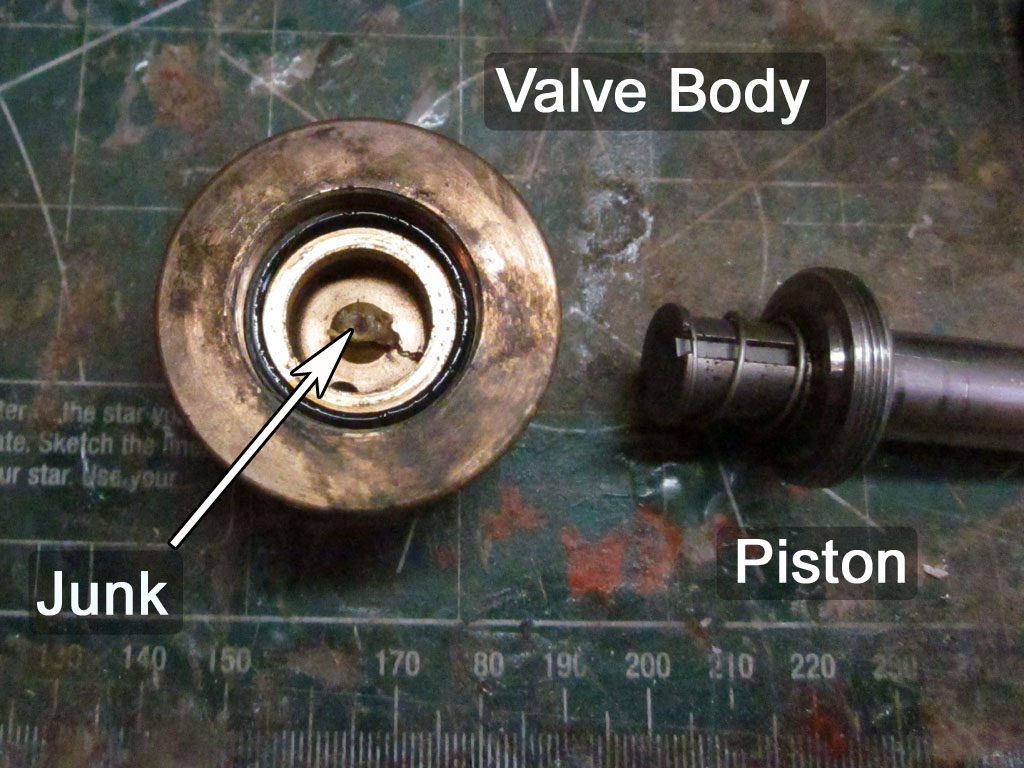

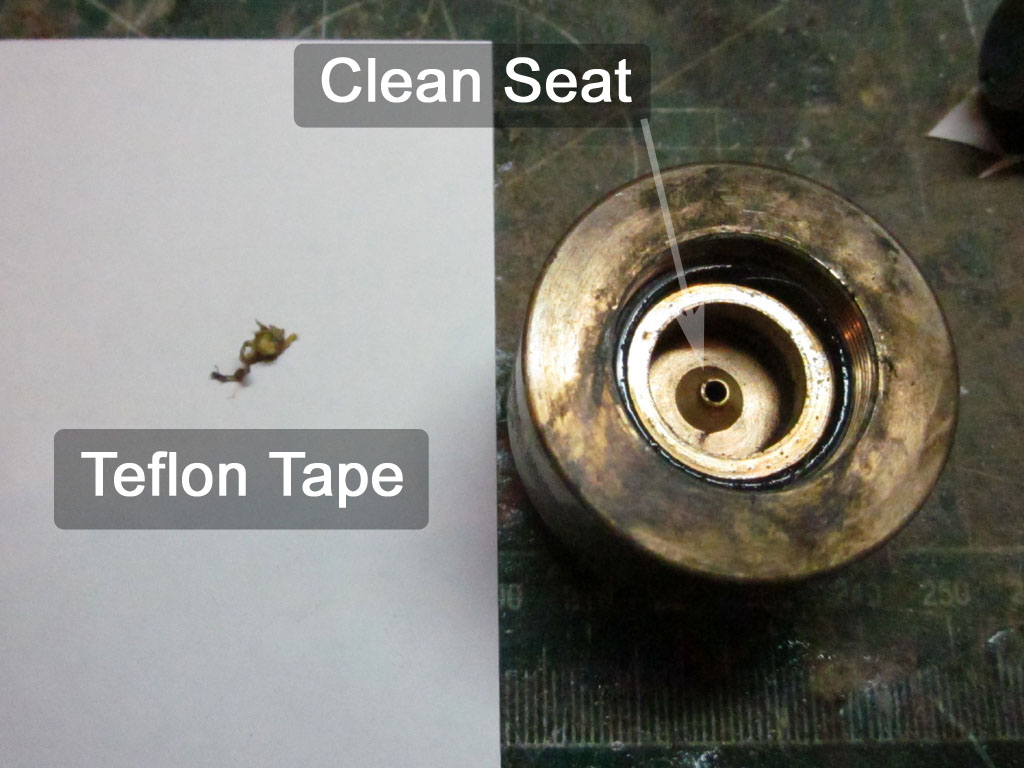

Once dissembled I could immediately see that there was some “bonus” material on the brass seat. This was preventing the piston from being able to make a proper seal, resulting in a slow leak through. Good old Teflon tape from somewhere had made its way inside the valve body.

Note: The depression in the compliant HWH plunger seat does not appear to be perfectly concentric on the piston face. This may make the disassemble / clean / reassemble difficult in that may not allow the seat interface to align and seal properly depending on how you put it back together.

And now for some pics