HWH Valve Replacement

From time to time the leveling solenoids on the front and rear hwh six packs develop leaks. The leaking of the o-rings is easy to find with the soap bubble test, and replacing them an easy project. Leaks inside the valves, at the seats, or internal o-ring, can be more difficult to diagnose and often exhibit themselves as leveling issues.

The six packs are easy to locate, they have airlines on one side and solenoid valves on the other. On each six pack there will be 6 solenoids. (2) are the R/L travel solenoids that work with the ride height control valve when you have a green travel light. (2) are the dump solenoids and (2) two are the raise solenoids. The dump and raise solenoids work when the system is in level mode.

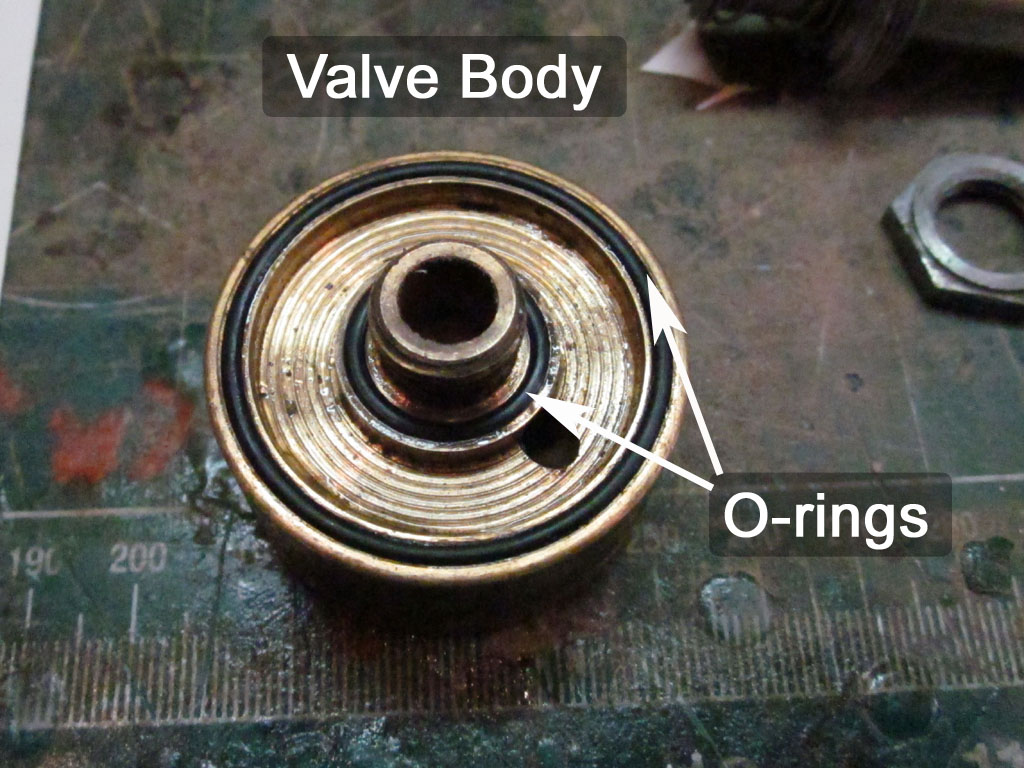

O-ring Replacement

The valves are screwed on to the manifold with two o-rings, an inner o-ring and an outer o-ring. Those O-rings on the face of the valve make the seal against the “6-pack” manifold. The official HWH part number for the replacements is RAP6554.

The OEM kit contains (1) #015 and (1) #028 o-ring, both with a standard round cross section. You should be able to go to any hardware store and find the same ones (Buna-N / Nitrile)

Note that you can also easily remove the coil from each valve stem, its just held on by the nut on the end, remove that and it will lifts off. Sometimes that gives you a bit more room to maneuver. Don’t take off more than one at a time unless you mark where each one goes so you return them to the right stems.

The manifold should not be pitted / scratched where the o-rings seat. You should also clean off any debris on / around the seating surface, taking care not to knock any into the exposed openings.

A little grease on the o-rings is recommended by HWH, petroleum jelly or silicon grease are both good for this. If you use other than Buna-N / Nitrile materials (the most common) then you should check for material compatabilty. The lubrication is necessary to prevent tearing the o-rings as you lightly snug the valve down.

How tight to install, not sure if its 1/4 or 1/2 turn past finger tight, but you will get a feel for that when you remove the first one. Its a similar feel for an oil filter, with the same don’t over tighten warning.

New Valves

The HWH part number for our valves is RAP1940 for the raise and travel parts (3/32 orifice). The dump valves are a different number (RAP????) as they have a larger 5/32 orifice so they can move more air.

The valves contain a cone-shaped seat, a plunger with a compliant face insert that rests on the seat, and a spring keeps it closed when the solenoid coil is not energized.

Replacing the HWH Plunger

Sometimes the seal at the seat will fail, maybe due to grit on the seat or often due to the compliant surface taking on a deep set with age. Although the valves are serviceable, you can take it apart to repair, finding a replacement piston/seat has been a problem. HWH will not sell just the piston, although they will service valves for less than 1/2 the cost of a full replacement.

Its been reported by some that you can reface the plunger face on a lathe, providing a new clean surface to the compliant face.

Others have used a Skinner replacement plunger V5-207-N (~$18) to replace the old plunger, however that has a smaller compliant seat of ~.20 vs the >.30 diameter on the original.

Use that information at your own risk, I am not endorsing use of the replacements.

The measurements of the piston are:

- Main Diameter: .442

- Length: 1.175

- Diameter at seat: .542

- Diameter of seat: .290

O-Rings and Lubricants

There are O-ring materials that are not compatible with Vaseline petroleum jelly (same is true for silicone grease on some silicon O-rings). From the O-ring design and materials guide:

Hydrocarbon-based materials, such as petrolatum. As a clear to yellowish semisolid, petrolatum is better known as petroleum jelly (Vaseline®), but it is also available in liquid form. Petrolatum is typically suitable for use with

- Nitrile / Buna N (the most commonly used elastomer for O-rings and other sealing devices.)

- Chloroprene (often referred to by the trade name Neoprene)

- Polyurethane (Adiprene, Estane, Millathane, Morthane, Pellethane, Texin, Vibrathane)

- Silicone (general usage)

- Fluorosilicone (fluorovinylmethyl silicone rubber)

- Fluorocarbon (Viton)

You can also use the following site to check for chemical compatibility